Gsort: Case Study

A review of dry separation by different densities..

Comminution is the action of reducing a material, especially a mineral ore, to various sized particles or fragments. When combined with sorting at each separation stage during processing, this method is known as preconcentration per stages.

Dry separation by different densities is a method of preconcentration for ore processing. The dry preconcentration method has numerous advantages for mining operations, explored in the overview below.

Challenges

Traditional processing vs selective concentration for mining.

Conventional wet processing generates several environmental problems and risks for mining companies and often carries high operational costs , associated to the huge water mixed with rejects generated.

New environmental regulations and pressure from stakeholders have set new standards and requirements for energy and water usage, especially for tailing ponds (water lagoons) in the mining industry.

These changes present challenges for the industry in separating and sorting materials as cost-effective and environmentally friendly as possible.

Requirements:

Several requirements must be met for the effective dry separation of minerals.

• The minimum difference in absolute density between heavy fraction and light fraction should be around 20%

• Before density separation, it is necessary to break up the material via crushing to segregate the minerals

• Maximum particle sizes depend on the absolute density and defines the power requirement of the GSort fan; minimum size depends on the moisture; the limit is where the product loses the "free flow" condition

Approx. Minimum particle size: 0,5 mm

Approx. Maximum particle sizer: 80 mm

Solution:

ALLGAIER provides a complete alternative for the dry processing of ore.

The GSort is an innovative densimetric table that provides solutions to the mining industry's environmental and operational challenges.

Dry densimetric separation is achieved on a vibrating, inclined base. Rising airflow crosses this base and has two effects on the material. Less dense products float without touching the bottom plate and slide to the lower portion of the inclined table. Denser product contacts the table and is pushed towards the top due to the vibration. The more significant the difference in density of the products, the larger the grain size bands can be.

Dry preconcentration delivers enormous advantages when compared to traditional processing.

Less energy is needed to reduce the particle size (Mogensen sizers will complement crushing equipment in each conminution step.

Lower mass flow advancing to the following stages due to the effect of preconcentration results in less energy, water, and wear on equipment.

An added benefit is the reduced size requirements of downstream equipment.

GSort - Ore Processing

Results:

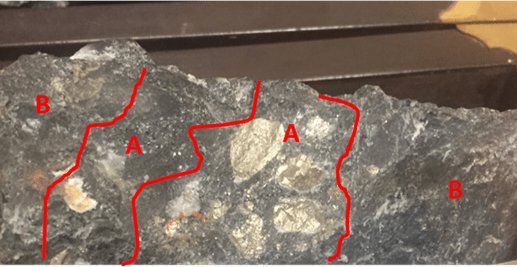

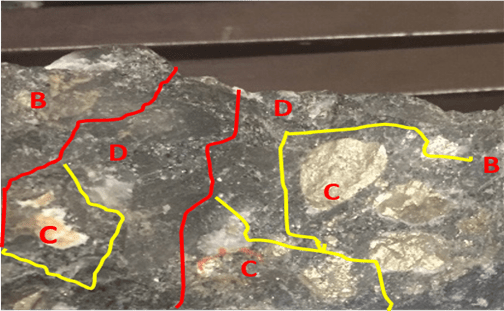

A- Barite Project of an Industry Leader in Mexico 2019

Customer Challenges:

1. Conventional wet processing lead to an increase in operational costs in a water scare environment.

2. The customer could not process tailings (3-25 mm) using traditional wet/jig processing.

3. Unable to meet the minimum market concentration requirement of 4.1 t/m3 for raw materials coming from pit areas under a concentration of 3,5 t/m3 processed with current jigs (concentration up to +0,5 t/m3).

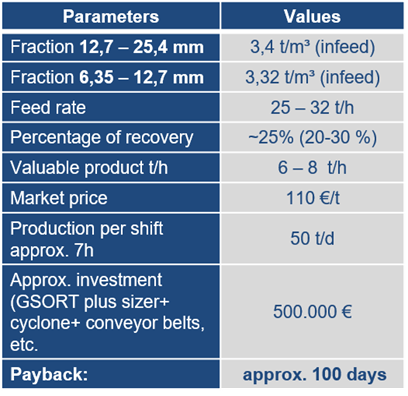

Customer Outcomes: Installation – GSort + MSizer:.

Customer background: First Gsort was purchased in 2018 to upgrade productions processed after successful test trials. A 2nd Gsort + MSizer installation was added in 2019.

1. The customer realized a great return on investment with a payback period of about 100 days.

2. After adding a 2nd Gsort plus a Mogensen sizer, the customer could process tail material between 3 – 25 mm not only from their mine but also from third party mines.

Barite separation: the GSort can achieve up to 4,44 kg/liter.

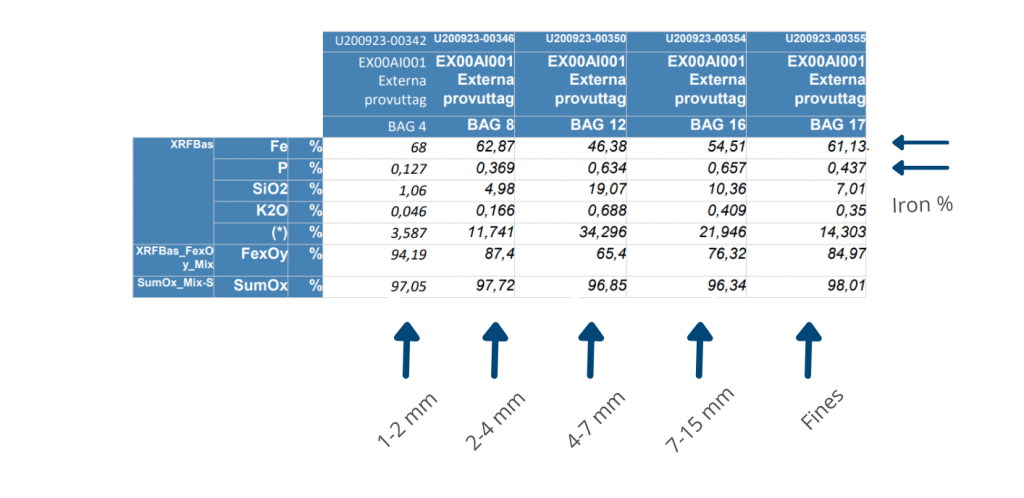

B - Tests with iron ore (hematite) – Sweden 2020

Test trails with hematite (iron content 69,9%) 1-15 mm from Sweden. Customer lab test results shown below:

Fe (%) of raw material (ROM) was 45%.

The tests showed that it is possible to reduce the flow of material in a dry way by 35%, obtaining a final iron concentration of 64% and a recovery of Fe greater than 90%.

GSort Densimetric Table Advantages:

As a result of dry separation by different densities using the Gsort, our customers were able to benefit from:

Better performance: The GSort beat established sorting methods with a performance increase of up to 80%.

Reduced operating costs: As a result of improved water management and reduced energy costs. The Gsorts design also lowers assembly, disassembly, and transportation costs.

Environmentally friendly processing: As a result of reduced energy consumption per metric ton, lower use of surface and lower water usage; in total, less environmental footprint and CO2 emissions.

Applications:

The Gsort densimetric table is suitable for a wide range of applications for various industrial processes.

| INDUSTRIES | MINING |

| - Recycling - Plastic recycling - Building materials - Fine metals - Glass recycling - Cable waste - E-waste - Slag | - Baryte - Coal - Iron - Lignite - Tungsten - Zirconium - Ilmenite |

To learn more about Allgaier Mogensen's full range of industrial process technology for waste and recycling applications, click here.